PROPULSION

The Propulsion team is responsible for designing, manufacturing, and testing all the components that deal with flowing propellant into our engines. The team designs the engines, injectors, valves, feed systems, and control systems that make up an effective propulsion system. Propulsion work is not limited to vehicles, test stands and ground support equipment are also essential to developing propulsion systems.

Join the Propulsion team!

Propulsion is always looking for more members interested in learning about fluid systems, machining, mechanical design, CAD, CFD, thermodynamics, and MATLAB.

SUBTEAMS

Fluid Systems

Fluid feed systems are critical for handling our rocket’s liquid propellants. Several different fluid systems are used on YJSP for various purposes such as the vehicle feed system to deliver propellant to our flight engine, the ground support equipment which fills the rocket tanks with propellant, and various test stands we use to characterize our engines and components on the ground prior to launch.

Engine Design

The Engine Design team designs, manufactures, and tests engines, injectors, and ignition systems. Their most ambitious projects undertaken to date include regeneratively cooled, ablative, and heatsink engines of varying size as well as coaxial swirl, impinging, and pintle injectors developed in support of these engines.

Controls

The Propulsion Controls team models the dynamics of our fluid systems. The main controls project is the active pressurization system which uses bang-bang control to maintain pressure and flow rate into our engines. Bang-bang control is utilized on both our engine test stand and on a future vehicle. The controls team also explores novel pressurization techniques and challenging control problems like throttling and thrust vector control.

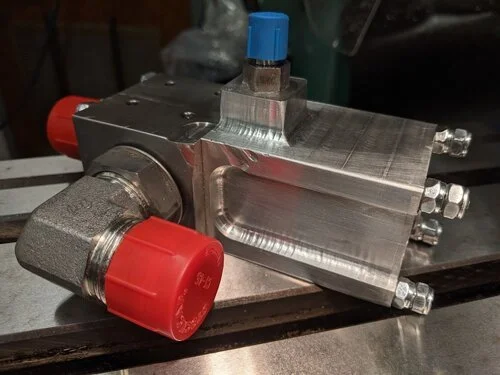

Valves

The valves team designs entirely custom components as well as custom valve actuators. Custom components are manufactured and tested in-house by students. The Fuel Main Valve (FMV) is a custom sleeve valve used to control the flow of fuel on GoldiLOX, and it has now been proven in flight. The Oxygen Quick Disconnect (OQD) is another custom component with flight heritage on GoldiLOX and it is being upgraded for future missions.